Food safety is a scientific discipline describing handling, preparation and storage of food in ways that prevent food-borne illness. This includes a number of routines that should be followed to avoid potentially severe health hazards. The tracks govern safety between industry and the market and then between the market and the consumer:

(1) In considering industry to market practices, food safety considerations include the origins of food including the practices relating to food labeling, food hygiene, food additives and pesticide residues.

(2) In considering market to consumer practices, the usual thought is that food ought to be safe in the market and the concern is safe delivery and preparation of the food for the consumer.

WHO

The World Health Organization (WHO) is a specialized agency of the United Nations (UN) that is concerned with international public health. Although food can serve as a growth medium for bacteria which can cause food poisoning, in theory food poisoning is 100% preventable. The five key principles of food hygiene, according to WHO are:

1.Prevent contaminating food with pathogens spreading from people, pets, and pests.

2.Separate raw and cooked foods to prevent contaminating the cooked foods.

3.Cook foods for the appropriate length of time and at the appropriate temperature to kill pathogens.

4.Store food at the proper temperature.

5.Do use safe water and cooked materials.

ISO 2000 and ISO2200

A general derivative of ISO 9000, ISO 2000 is a standard developed by the International Organization for Standardization dealing with food safety. ISO 22000 international standard further specifies the requirements for a food safety management system that involves interactive communication, system management, prerequisite programs, HACCP principles.

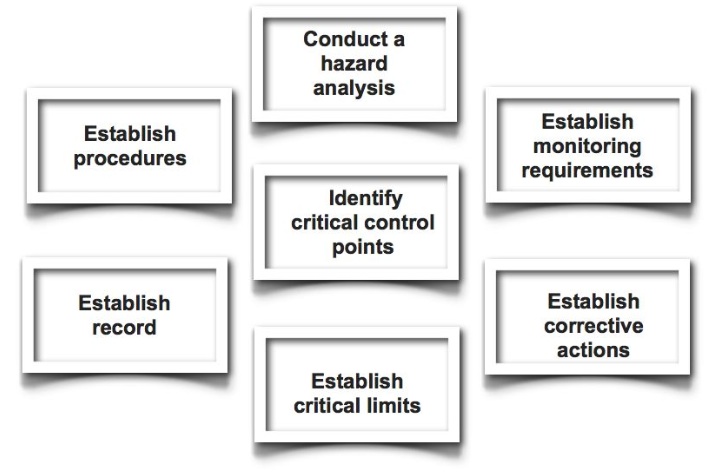

The HACCP seven principles

Principle 1: Conduct a hazard analysis

Plans determine the food safety hazards and identify the preventive measures the plan can apply to control these hazards. A food safety hazard is any biological, chemical, or physical property that may cause a food to be unsafe for human consumption.

Principle 2: Identify critical control points

A critical control point (CCP) is a point, step, or procedure in a food manufacturing process at which control can be applied and, as a result, a food safety hazard can be prevented, eliminated, or reduced to an acceptable level.

Principle 3: Establish critical limits for each critical control point

A critical limit is the maximum or minimum value to which a physical, biological, or chemical hazard must be controlled at a critical control point to prevent, eliminate, or reduce to an acceptable level.

Principle 4: Establish critical control point monitoring requirements

Monitoring activities are necessary to ensure that the process is under control at each critical control point.

Principle 5: Establish corrective actions

These are actions to be taken when monitoring indicates a deviation from an established critical limit. The final rule requires a plant’s HACCP plan to identify the corrective actions to be taken if a critical limit is not met. Corrective actions are intended to ensure that no product injurious to health or otherwise adulterated as a result of the deviation enters commerce.

Principle 6: Establish procedures for ensuring the HACCP system is working as intended

Validation ensures that the plants do what they were designed to do; that is, they are successful in ensuring the production of a safe product. Plants will be required to validate their own HACCP plans. Verification procedures may include such activities as review of HACCP plans, CCP records, critical limits and microbial sampling and analysis.

Principle 7: Establish record keeping procedures

The HACCP regulation requires that all plants maintain certain documents, including its hazard analysis and written HACCP plan, and records documenting the monitoring of critical control points, critical limits, verification activities, and the handling of processing deviations.

*Reference: wikipedia