The food industry in Taiwan has been exposed to strong challenges from importers since the late 1970s. The Council of Agriculture initiated the Chinese Agriculture Standard (CAS) quality certification system in order to assist the industry. The Ministry of Economic Affairs enforced food GMP as another quality certification system. CAS has expanded to cover 11 product categories, 182 certified food processing or retailing facilities, and 3,400 products. The major emphasis is on domestic origin, freshness, high quality, and product safety. Food GMP focuses on product quality and hygiene practice in the manufacturing process. By the end of 2001, there were 299 certified food GMP factories with over 3,400 products.

While CAS and GMP evolved as voluntary high performance standards for average food products, the Department of Health later published GHP to set the mandatory minimum sanitation standards for food processors. GHP encompasses the processing premises, construction, equipment, personnel hygiene, standard sanitation operation procedures, as well as water, suppliers, processing, storage, and transportation control, as well as record keeping and personnel training procedures.HACCP arrived last amongst the certification systems. Certain pilot HACCP programs concerned with seafood and several other food sectors have been undertaken. The lunch box processing industry is a successful example. In the first year of the program (1998), 23 out of 25 participating lunch box processors were granted pilot HACCP certifications. In the second year, the reported number of food-poisoning victims at schools decreased by 30 percent as compared to the previous year. By the end of the third year, a total of 193 lunch box processors and food establishments were certified under the pilot HACCP program which led to further 28 percent reduction in the number of food-poisoning victims that year.

Reference: Quality Enhancement in Food Processing Through HACCP (Hazard Analysis and Critical Control Point) ©APO 2004, ISBN: 92-833-7041-4

Sunshine Energy’s instant cooling machine in the context of food safety:

Taiwanese foods are unforgettable and very delicious, but some delicious Taiwanese cuisines are too far to taste. So, these restaurants would like to do the home delivery business to expand the market, and the clients can taste and the business of the food will be better. But it’s not just talking; to do is a difficult thing. This is because the quality of some restaurants is unstable; this will cause the ruthless criticizing of key pals. These criticizing will lead to bad business. So, if you want to expand your business in the online market, you have to pay attention to the food sanitation and food safety. To stabilize the quality, the key point is the number of the bacteria.

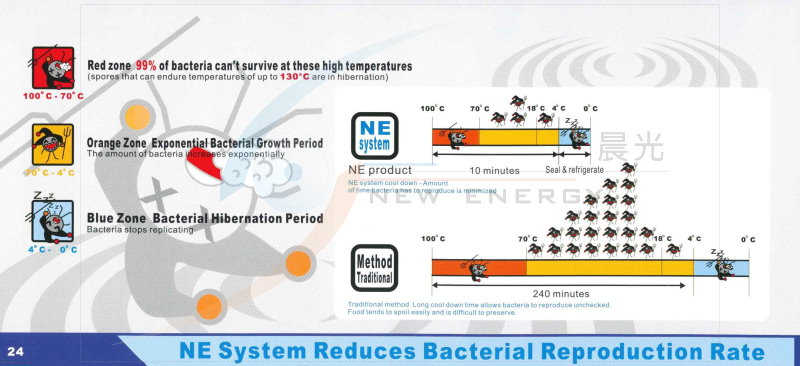

The number of bacteria and the percentage of the rotten food are proportional. This is a good way to use bacteria number as a sign of the quality of food. That’s because we can’t tell the number of bacteria by our own mouth feel, when we find out the food is already gone bad, the number of bacteria is around 250 million. This means that we could know the exact number of bacteria, so we can’t control the quality by our month.As the picture above says, if we wants to kill all the bacteria, we have to heat up until 130°C. But this temperature can’t be reach on level ground, and the bacteria will not dead when boiled. The cooling is slow, so the bacteria will grow rapidly, especially the most nutritious food. To let the bacteria go to sleep and stop to grow will be a good choice to control the quality. And this is the reason why exist instant cooling machine.