Food Safety and Main Hazards

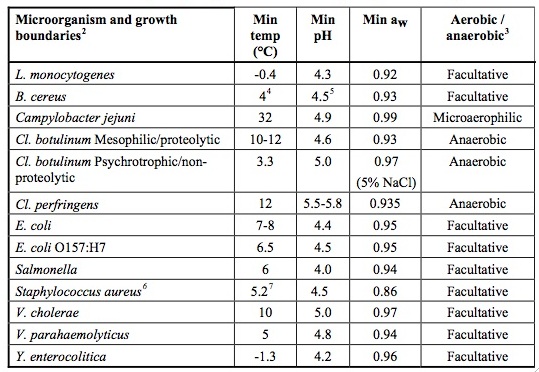

Microbiological hazards⎯Chilled foods are very sensitive to microbiological contamination, growth and toxin development. The table below lists the pathogenic microorganisms of concern along with their principal growth boundaries. While all of these pathogens need to be taken into consideration, cold growing pathogens such as Listeria monocytogenes, psychrotrophic Clostridium botulinum and psychrotrophic Bacillus cereus are of particular relevance to chilled food.

To control these hazards the following must be taken into account:

- Supplier selection, specifications and control of incoming raw material

- Appropriate raw material storage and stock rotation

- Product/process design and control measures

- Hygienic processing conditions

- Allocation of appropriate product shelf life and instruction of use

- Maintenance of the chill chain during distribution and sale

Chemical hazards⎯Chilled foods, like other food products, are also subject to contamination by environmental contaminants and residues from pesticides or veterinary drugs. Compliance of raw material with the relevant legislation is essential.Supplier selection, evaluation and follow-up are the best control measures. Chemicals such as cleaning agents, lubricants and pest control materials may also present on-site chemical hazards. The correct use of food-grade chemicals, where appropriate, and application of GMP are the best control measures.

Physical hazards⎯Physical hazards might include foreign bodies such as metal, glass, wood and bone fragments. Their control is ensured by raw material quality (specifications, supplier evaluation) and provisions applied during processing (e.g. metal detectors after packaging, filters in line).

Reference: RECOMMENDATIONS FOR THE PRODUCTION OF PREPACKAGED CHILLED FOOD, ECFF Recommendations December 2006

With concerns over food safety on the increase and an alarming number of food poisoning cases attributed to food eaten outside of the home, it is essential that every caterer takes steps to ensure that all food handling staff are supervised and/or trained in food hygiene matters. Any staff member handling food, whether open or packaged and including drinks and ice, should receive the instruction / training to a level suitable for their role. Same important is that a written or verbal instruction must be in place before staff members start working at an establishment for the first time.

Below is a quick overview of key points for staff to be made aware of:

- Keep yourself clean and wear clean clothing

- Always wash your hands thoroughly: before handling food, after using the toilet, handling raw foods or waste, before starting work, after every break and after blowing your nose

- Tell your supervisor before you start work of any skin, nose, throat, stomach or bowel trouble or infected wound. You are breaking the law if you do not.

- Ensure cuts and sores are covered with a waterproof, high visibility dressing

- Avoid unnecessary handling of food

- Do not smoke, eat or drink in a food room, and never cough or sneeze over food

- Do not prepare food too far in advance of service

- Keep perishable food either refrigerated or piping hot

- Keep the preparation of raw and cooked food strictly separate

- When reheating food ensure it gets piping hot

- Clean as you go. Keep all equipment and surfaces clean

- Follow any food safety instructions provided either on food packaging or from your supervisor.