Hot Filling

Hot filling is a great method for packing before rapid cooling machine invented.

There are few reasons why hot filling is a great method in old time:

- There is no efficient cooling method.

- People do not know much about controlling environment of packing area.

- Can not make sure whether packing material is clean or not.

So it can disinfect by the high temperature of food during hot filling.

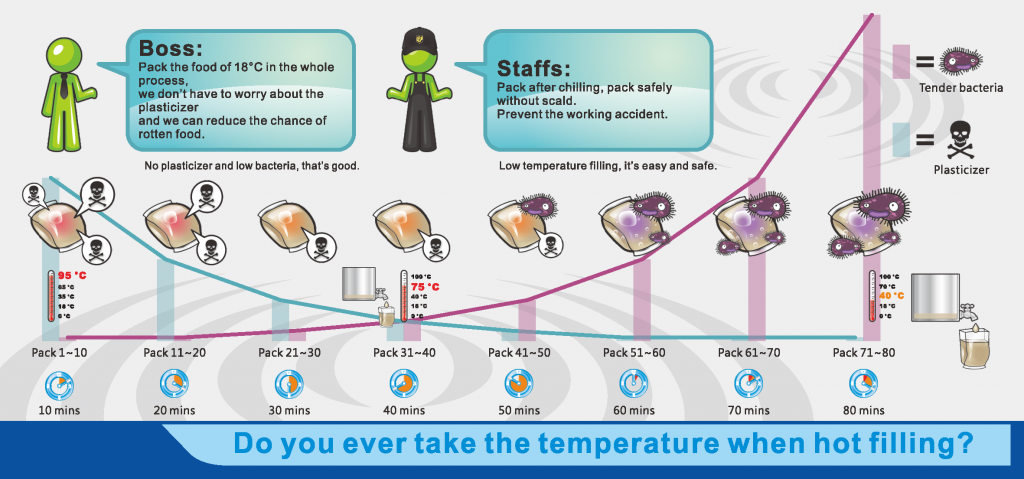

The definition of hot filling as follows:

- To avoid the bacteria breeding fast(during 20ºC~70ºC), the temperature should higher then 70ºC while filling.

- Food temperature need above 70ºC when last packing completed, we can suppose the temperature was very high while starting packing.

But hot filling might cause few problem :

- Scald.

- Too hot to filling by staff.

- Product will be overcooked by the heat, texture of food might be changed.

- Plasticizer releases from plastic bag.

- Cooling method after hot filling.(If it takes long time to chill, bacteria will breed in the plastic bag)

- Can not vacuum packing due to the heat inside the bag will produce hot air.

- Packing material is expensive.

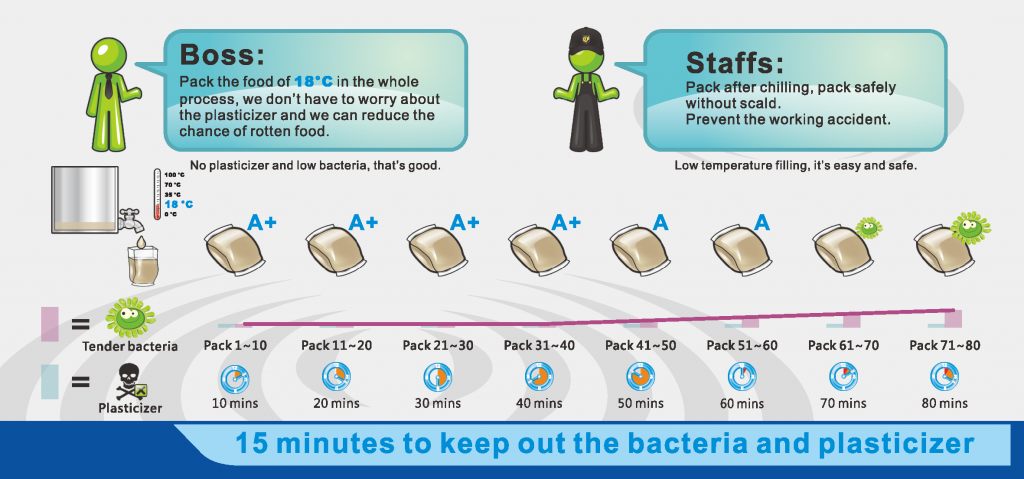

Cold Filling

Advantages of packing after rapid cooling:

- No scald.

- No plasticizer release from plastic bag.

- Preserve original flavor of food.

- Avoid of overcooking, keep the texture.

- Rapid cooling makes food pass the temperature that bacteria is easy to greed in a short time, lower bacterial number can extend preserve time.

- No heat comes out after rapid cooling, it’s good for vacuum packing.

- Lower cost of packing material.